Sewage Treatment

Our Department’s core responsibilities include the provision of a comprehensive sewage treatment service for Hong Kong citizens. With advanced technology, we are able to remove most of the pollutants from sewage to a level that meets local environmental standards. We are mindful also of the need to improve our sewerage coverage and treatment facilities in line with a sustainable development of Hong Kong. |

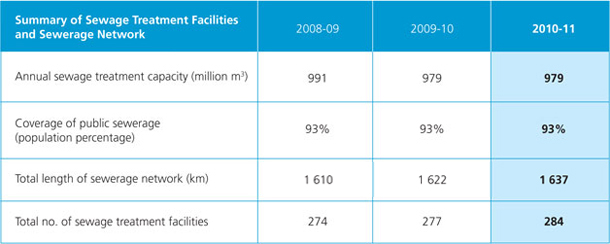

||||||

| Our Sewerage System To cover the entire Hong Kong, we have a huge sewerage network with a total length of 1637 kilometres, which is about the distance between Hong Kong and Jinan in Shandong Province, serving 93 per cent of our population. At present, we operate a total of 284 sewage treatment facilities, including 67 sewage treatment plants and 217 sewage pumping stations. On average, we treat 2.68 million m3 of sewage every day. |

||||||

|

||||||

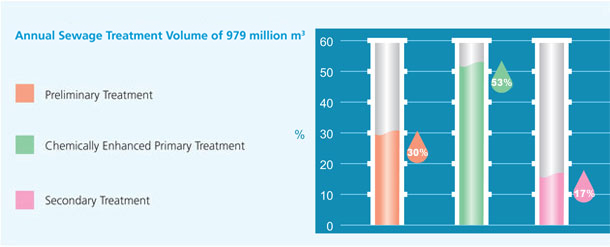

| In 2010-11, we treated 979 million m3 of sewage in total, of which 30 per cent underwent preliminary treatment; 53 per cent, chemically-enhanced primary treatment; and 17 per cent, secondary treatment. | ||||||

|

||||||

|

||||||

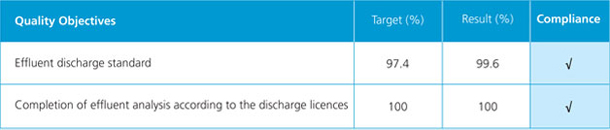

| Sewage Treatment Performance Committed to providing world-class sewage treatment services, we follow a set of strict discharge standards and monitor the performance of various sewage treatment facilities. Control and monitoring are conducted by our accredited laboratory. In 2010-11, except for two isolated incidents outside our control, we achieved full compliance with the discharge standards. |

||||||

| Quality Objectives for Effluent Control in 2010-11 | ||||||

|

||||||

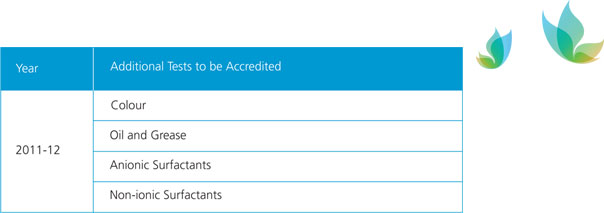

| Professional Laboratory Services Strict quality compliance relies on good support from our professional laboratory services. Our laboratory has gained accreditation since 1999 for testing environmental samples of both water and wastewater under the Hong Kong Laboratory Accreditation Scheme operated by the Hong Kong Accreditation Services of the Innovation & Technology Commission. The number of tests accredited doubled from 7 to 14 between the fiscal year of 1999 and 2010. |

||||||

| We will continue to upgrade our testing service and quality. In 2011-12, four more tests are expected to be accredited. | ||||||

|

||||||

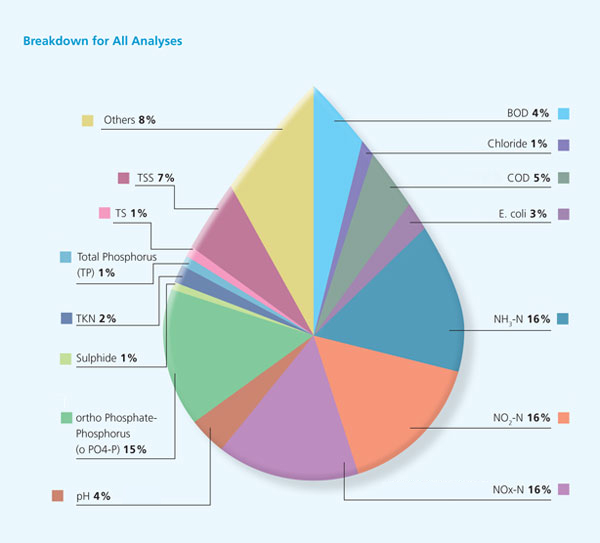

Shatin Central Laboratory — Analytical Services |

||||||

|

||||||

|

||||||

|

||||||

| Progress in 2010-11 During the year, we successfully put the advance disinfection facilities at Stonecutters Island Sewage Treatment Works (SCISTW) in full operation. This helped restore the water quality in four Tsuen Wan beaches to a level suitable for swimming. We also awarded three major works contracts for upgrading SCISTW and the preliminary treatment works on the northern shore of Hong Kong Island — bringing the construction works of HATS Stage 2A to its full swing. The major upgrading works at SCISTW include the construction of a large underground pumping station, with a 55-metre internal diameter and a depth of about 40 metres; a sewage tunnel connecting the existing and new pumping stations; additional double-tray sedimentation tanks; new sludge de-watering facilities; a new effluent tunnel; deodorisation units; disinfection facilities; expansion and coverup of existing sedimentation tanks; a new control system plus other ancillary facilities. Upgrading of the Preliminary Treatment Works at North Point, Wanchai East, Central, Sandy Bay, Cyberport, Wah Fu, Aberdeen and Ap Lei Chau will also be carried out progressively. All the awarded works contracts are making satisfactory progress. Meanwhile, two other upgrading works contracts under HATS Stage 2A, will be awarded in mid-2011. On the sewage conveyance system, the construction of three tunnels, of which the contracts commenced in mid-2009, is progressing satisfactorily as well. The sewage tunnels, from North Point via Sai Ying Pun to Stonecutters Island and from Aberdeen to Sai Ying Pun, will be constructed using the drill-and-blast method. Diaphragm wall and pipe pile wall construction for all the vertical shafts have been completed and the excavation of the vertical shafts is in progress. Tunnel excavation will commence upon the completion of production shafts. The remaining tunnel from Ap Lei Chau to Aberdeen is being constructed by horizontal directional drilling method after the pilot holes were finished in early 2011. We are targeting to commission HATS Stage 2A by 2014-15. |

||||||

|

||||||

| Covers installed at sedimentation tanks | ||||||

|

||||||

|

||||||

| Lamma Island's Eco-friendly Sewage Treatment Facilities We commenced the construction of the first sewage treatment facilities at Yung Shu Wan and Sok Kwu Wan respectively in May 2010 with a goal to reduce pollution in nearby watercourses and receiving waters of Lamma Island. Given the limited land at both work sites and also the close proximity to sensitive receivers of fish culture zones at Sok Kwu Wan, we decided to adopt a new technique — submerged-type Membrane Biological Reactor — for the treatment system. This will minimise land uptake for secondary treatment and will also raise the effluent quality. This advanced technology makes use of membrane modules submerged in biological reaction tanks. When the screened sewage infiltrates the membrane module through 0.4 micron pores on the membrane sheet before being discharged to the sea via submarine outfalls, the suspended solids and Escherichia coli in it can be greatly reduced to a level that meets the requirements of the discharge licence. The use of this new technology also replaces the final settlement tanks and disinfection facilities, used in conventional sewage treatment system. |

||||||

| Odour Management Overview Odour management is one of our priority areas in delivering quality services to the community. Malodorous gases generated throughout sewage conveyance and treatment not only damage our facilities but also cause a nuisance to the public concerned. To alleviate the odour problem and to provide a better work environment for our plant personnel, we adopted measures to prevent the formation of malodour. At the same time, we contain these compounds and treat them by physical, chemical and biological means. New Technology for Odour Management Odour in sewerage, normally associated with hydrogen sulphide (H2S), is generated due to prolonged retention of septic sewage in conveyance network in the absence of oxygen. Adding oxygen or its substitute could prevent the formation of odorous compounds. Calcium nitrate dosing is often adopted at sewage pumping stations as an alternative oxygen source to prevent septicity of sewage in the downstream rising mains. In 2010, we introduced a new method called ‘Superoxygenation’ at our Tung Chung Sewage Pumping Station. Large amount of oxygen is dissolved in the sewage to maintain the latter in an aerobic condition along the rising mains, thus preventing the generation of hydrogen sulphide. Odorous compounds inside sewage pumping stations and sewage treatment works should, before treated, be contained and kept at source to prevent their release to the atmosphere. An example is a tailor-made enclosure for the inlet screen at Ho Pong Street Sewage Pumping Station. The enclosure stops odour emission from the inlet screen to other parts of the building. The subsequent deodorisation removes the odorous compounds. The contained odorous air should be properly treated by deodorisation unit to an acceptable level before release. Depending upon the strength and nature of the odorous gases, biotrickling filter, chemical scrubber, activated carbon adsorber, or a combination of these, are applied at various pumping stations and treatment works. Stanley Sewage Treatment Works Signals Sustainability The Chief Executive, in his 2009-10 policy address, presented a new initiative that called for a planned development of underground space — involving a better use of rock caverns — as part of Hong Kong’s pursuit of sustainable development. A study was commissioned by the Civil Engineering and Development Department to explore the possibility. The use of caverns or underground space for sewage treatment works is not brand new to Hong Kong. In 1989, the need for a sewage treatment facility was identified under the Stanley Sewerage and Sewage Disposal Scheme. To maintain the scenic area around Stanley, the cavern option was adopted. Stanley Sewage Treatment Works is the first secondary treatment plant accommodated inside caverns. The construction of the treatment works commenced in November 1990 and commissioned in February 1995. The facility was housed inside three large caverns, each of about 120 metres long, 15 metres wide and 17 metres high, and connected by over 450 metres of road access, ventilation tunnels and shafts. The design treatment capacity is 11600m3 per day, serving a population of some 27000 in the catchment area. This Stanley facility was also designed with objectives to minimise carbon footprint, odour generation and construction cost of civil engineering works. These objectives were accomplished by adopting distinct design features such as extended aeration process and laminar settlers for final sedimentation tanks. Unlike treatment plants built on open ground, the Stanley facility required special attention on fire safety, gas detection, ventilation and emergency evacuation. In brief, the Stanley facility signifies a proven experience of constructing, operating and maintaining a secondary sewage treatment works inside caverns. |

||||||

|

||||||

| Entrance to Stanley Sewage Treatment Works | ||||||