| Sewage treatment plays a very crucial role in our services for Hong Kong. By means of different types of treatment processes and advanced technologies, most of the pollutants, toxic materials and bacteria in the sewage will be removed to a level meeting the environmental standards. | |||||||

| Overview of Sewage Treatment and Sewerage System | |||||||

For the collection of sewage from the territory, we have developed a huge sewerage network with a total length of 1,622km, which is almost the distance from Hong Kong to Jinan, Shandong. Our sewerage system is serving 93% of the population in Hong Kong. At present, we are operating 277 sewage handling facilities, including 66 sewage treatment works and 211 sewage pumping stations. We treat on average 2.68 million m3 of sewage collected from our sewerage network every day. |

|||||||

|

|||||||

| In 2009-10, we treated 979 million m3 of sewage in total. 29 per cent of the sewage received Preliminary Treatment, 54 per cent received Chemically Enhanced Primary Treatment (CEPT) and 17 per cent received Secondary Treatment. | |||||||

|

|||||||

Sludge is produced during the sewage treatment process. The total quantity of sludge collected in 2009-10 was 277,460 tonnes. It required about 21,300 container vehicle trips to deliver the sludge for disposal at the landfills. We have been properly maintaining our sewage collection, treatment and disposal facilities to ensure their efficient and effective operation. We will continuously improve the sewerage coverage and treatment facilities helping the sustainable development of Hong Kong. Integrating our professional team, advanced technologies and facilities, we are making our best endeavour for providing world-class sewage collection and treatment services for Hong Kong. |

|||||||

| Sewage Treatment Performance | |||||||

Our Laboratory commits to provide professional and high quality laboratory services for process control and effluent standard monitoring of sewage treatment works. Committed to providing world-class sewage treatment services, we have set a series of strict quality objectives to monitor our performance. In 2009-10, full compliance with all the targets was achieved. |

|||||||

|

|||||||

|

|||||||

|

|||||||

Professional Laboratory Services To meet HOKLAS requirements, strict quality control measurements are in place to satisfy requirements, including staff competency, standard of chemicals used with reference to International System of Units (S.I.) and standard equipment calibrated by authorized calibration organisations, etc. In addition, the laboratory participates in external proficiency testing programmes to demonstrate competence in performing specific tests. |

|

||||||

|

|||||||

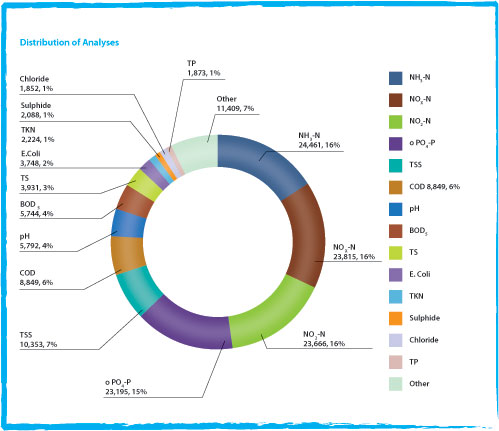

Shatin Central Laboratory - Analytical Services Extensive laboratory testing, which covers more than 14 types of analyses, has been carried out in our Shatin Central Laboratory. In 2009-10, the total number of analyses carried out by Shatin Central Laboratory was about 153,000. |

|||||||

|

|||||||

|

|||||||

| Progress in 2009-10 The HATS Stage 2A sewage conveyance system (SCS) comprises a network of interconnected sewage tunnels and vertical shafts. The vertical shafts collect sewage from the preliminary treatment works in North Point, Wan Chai East, Central, Sandy Bay, Cyberport, Wah Fu, Aberdeen and Ap Lei Chau. The collected sewage is conveyed to the Stonecutters Island Sewage Treatment Works via a total of 21km of deep tunnels with depths in general varying from 70m to 160m below sea level. The system essentially operates as a siphon to minimise pumping at its downstream end. The SCS is split into 3 tunnel sections for construction under 3 separate contracts, namely North Point via Sai Ying Pun to Stonecutter Island, Aberdeen to Sai Ying Pun and Ap Lei Chau to Aberdeen. |

|||||||

|

|||||||

In 2009-10, we achieved good progress in the implementation of the SCS. We completed the detailed design, obtained funding and awarded 3 tunnel contracts. The SCS will mainly be constructed by drill-and-blast method. Drill-and-blast method is chosen because in addition to providing more working space for temporary support installation; yielding a more controllable programme; and resulting in higher valued excavated rocks for re-use, it is also more versatile in controlling groundwater during construction, especially for the section of deep tunnel under the Victoria Harbour. The smaller diameter tunnel from Ap Lei Chau to Aberdeen will be constructed using horizontal directional drilling method, in which the tunnel drilling equipment has a remote control on directional steering to govern its horizontal and vertical alignments. Since the commencement of the tunnel contracts in July 2009, we have achieved good progress in the construction of shafts which involved diaphragm wall and pipe pile wall construction, grouting, construction of noise enclosure, and the installation of the mucking system. |

|||||||

|

|||||||

| Advance Disinfection Facilities at Stonecutters Island STW | |||||||

|

|||||||

| The construction of advance disinfection facilities at Stonecutters Island STW was completed and commissioning commenced in March 2010. Satisfactory results have been achieved since commissioning of the facilities. The two advance contracts for the Stonecutter Island STW upgrading works are progressing satisfactorily. For the remaining main works under HATS Stage 2A, we obtained funding approval from the Legislative Council in April 2010 and tendering of these works will proceed progressively. It is targeted that the HATS Stage 2A will be commissioned by 2014-15. | |||||||

|

|||||||

|

|||||||

Adopt Design-Build-Operate (DBO) contract procurement To optimise the life-cycle cost outcome and to account for the residual life of the major E&M equipment (normally with a design life of 20-25 years) upon completion of the DBO contract, an operation period of 15 years is set. A type of proprietary high-rate clarification facilities instead of conventional CEPT design will be built for removal of Suspended Solids and Biological Oxygen Demand from the raw sewage. The high-rate clarification facilities that combine optimised flocculation, internal and external sludge recirculation, thickening in two conjoined vessels would maximise hydraulic loading and treatment efficiencies. This advanced sewage treatment technology has gained popularity in Europe, North America and the Mainland China in recent years. |

|||||||

|

|||||||

|

|||||||

Sustainable Development Carbon audit, also known as carbon dioxide audit, is a method to identify and calculate the emission and removal of carbon dioxide, from different processes within the boundary of the entity. DSD has already engaged a consultant for drafting a guideline for conducting carbon audit for the sewage treament facilities in Hong Kong. Shatin STW, which is the largest secondary treatment plant in Hong Kong, was selected as the first sewage treatment works to conduct a carbon audit. |

|||||||

|

|||||||

|

|||||||

| Within this 23,334 tonnes of carbon dioxide emitted, about 70% were due to electricity supplied from the power station, which burns fossil fuel, for the treatment process. | |||||||

|

|||||||

The audit results indicate that conservation of electricity through the improvement in energy efficiency and the use of renewable energy would be the key for reducing carbon dioxide emission. Methane is a kind of biogas for producing renewable energy. During the sewage treatment process, sludge will be produced. The sludge is further treated anaerobically in the digesters and methane is produced. |

|||||||

|

|||||||

We utilise the biogas produced by this anaerobic process to generate electricity for the plant operation. Therefore, the demand of electricity supplied from the power station can be reduced by about 24% and reduce the carbon dioxide emission. Apart from the utilisation of renewable energy, green plant are able to remove carbon dioxide through photosynthesis. Thus tree-planting has been carried out in the sewage treatment facilities to reduce the carbon dioxide emission. |

|||||||

|

|||||||

Biotrickling Filter Various Deodorisation Technologies Activated carbon adsorber is more commonly adopted for low H2S or odour level environment or used as secondary polishing unit in sewage treatment works. The malodorous gas is introduced in the adsorber vessel and blown through the caustic impregnated activated carbon bed where the contaminants are entrained and oxidized. Chemical scrubber allows the contact of malodorous gas with a scrubbing solution. Odour contaminants are transferred from the gas stream to the scrubber liquid through adsorption, thereby oxidized by the scrubbing chemicals. Biological odour treatment uses microorganisms for dissolving the smelly substances in the gas. The major requirement of such a treatment technology is maintaining a suitable environment for growth of the required microorganisms. Therefore, its operation and maintenance costs are relatively low. Biotrickling filter uses the biological treatment technology to provide a very cost-effective and reliable solution for deodorisation. Advantages of Biotrickling Filter |

|||||||

|

|||||||

| The advantages of the biotrickling filter over activated carbon adsorber and chemical scrubber are its significant saving in terms of chemical usage, energy and water consumptions as well as minimum operation and maintenance requirements. | |||||||

|

|||||||

|

|||||||

Biotrickling Filter Installations With the satisfactory performance of the first biotrickling filter deodorising system, we decided to install more biotrickling filters at Shatin STW to treat the major odour sources at the primary sedimentation tanks, sludge digester overflow chambers, sludge holding tanks and sludge transfer pumping station. We will install more biotrickling filters at other sewage treatment facilities to better alleviate the odour problem.

|

|||||||